*Heating method: steam heating.

*The corrugations are: A, B, C and E

Ridge A: 35 teeth / 300mm, ridge height 4.6mm

B-groove: 48 teeth / 300mm, groove height 2.8mm

C-groove: 40 teeth / 300mm, groove height 3.6mm

E-groove: 88 teeth / 300mm, groove height 1.45MM

*Electric cassette quick replacement corrugated wheel system.

*The positive pressure blowing type no paste fork design is adopted, so that it can keep smooth when producing any paper size.

*Install the corrugated wheel under the machine and the pressure wheel above the corrugated wheel to reduce the center of gravity of the machine and reduce the vibration of the machine, so as to make the machine more stable during operation.

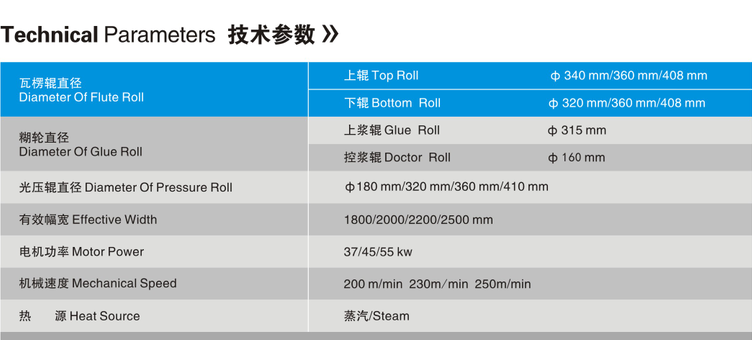

*Upper corrugating roller: 360mm in diameter, lower corrugating roller: 408mm in diameter. It is made of nickel chromium molybdenum alloy steel. After heat treatment, the hardness is above short 75 degrees, and the surface is treated with tungsten carbide. Guaranteed life: 40 million meters.

*Pressure roller: 450mm in diameter, made of carbon steel, with surface heat treated, ground and chrome plated.

*Paste roller: steel products with a diameter of 300mm, and the surface has been sandblasted and chrome plated.

*The automatic idling device of the paste roller is attached to prevent the paste liquid from drying on the surface of the paste roller when it is temporarily stopped.

*Paste cutting roller: steel products with a diameter of 180mm, and the surface is ground and chrome plated.

*The paste tray design is adopted, and the paste on the paste wheel is fully supplied. Therefore, when the machine speed changes, the paste film with appropriate thickness is maintained on the surface of the paste wheel.

*Stainless steel recovery paste tray is adopted, and water-cooled circulating cooling device is equipped.

*Core paper preheating roller: one steel product with a diameter of 552mm. It adopts independent transmission to effectively control and cooperate with the rotation of corrugated wheel.

*Face paper preheating roller: one steel product with a diameter of 552mm, rotating at a slow speed to keep the temperature uniform.

*The bearings of the upper and lower corrugated rollers and pressure rollers are lubricated with high temperature resistant grease.

*The adjustment of the upper and lower corrugated wheels and pressure wheels is controlled by the oil pressure system, and the paste wheel is controlled by the air pressure system.

*The gap between the lower corrugating roller and the pressure roller and the paste roller, and the gap between the paste roller and the lower corrugating roller and the cut paste roller are all adjusted electrically and displayed with numerical values. (use hydraulic motor)

*Different pasting gaps can be set according to the production speed and paper.

*The clearance between the pressure wheel and the lower corrugated wheel is adjusted, and the operation side and the drive side are adjusted separately and independently.

*Electric paste separating device is attached. (use AC motor)

*The sprinkler can be adjusted automatically and manually.

*Including steam swivel, stainless steel hose and steam pipe used in this machine.

*Two 15HP blowers are attached.

*A set of control box and operation panel are attached Open the front end of the operation box door to facilitate the front maintenance.

*Electric cassette truck: the battery supply motor drives the cassette truck to move, which can operate the cassette truck to move forward, backward or stop.

Copyright:Changzong Precision Machinery Technology Co., Ltd. Phone:13760982599 E-mail:tianzaicheng@163.com

Address:A2, Hesheng Industrial Zone, Sanshan Avenue, Nanhai District, Foshan City ICP:粤ICP备19133286号