According to the needs of customers, the machine can be used as the main machine for separating and forming the paper frame and the corrugated sheet, which can be automatically combined according to the needs of customers. In addition to the above equipment, we also provide computer production management system and other peripheral equipment. Assist in arranging orders and monitoring production, and make statistics and analysis of production results, so as to assist customers in effective production and management.

*The main function of this machine is corrugated board paper separation and pressing line

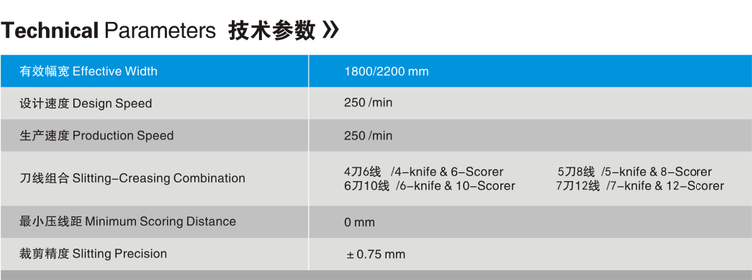

*It can be equipped with five knives and eight lines (four openings); Six knives and ten lines (five open); Seven knives and twelve lines (six open)

*The outer diameter of the moving shaft of the cutter wheel seat and the wire pressing wheel seat is 123mm, and the surface is precision milled and then hard chrome plated

*The thin blade is adopted, the tool diameter is 270mm, and the minimum cutting distance is 135mm

*Each knife adopts an independent sharpening system. The sharpening time and length can be set by computer, and manual sharpening can also be used to ensure that the cardboard incision is smooth and tidy

*The oil cooling system is used, and the Mo grinding knife system is actuated

*The cutter wheel uses A. C motor and ten frequency converter

*The outer diameter of the crimping wheel is 224mm, and the minimum crimping distance is 110mm

*The reel uses A.C. frequency conversion motor and frequency converter, which can operate synchronously with the double-sided machine

*The air pressure is used to control the upper cutter wheel and the upper wire pressing wheel to rise and fall, so the two connecting lines are replaced

*When the order is used, it is not necessary to cut off the order and stop the machine

*The size of paper separation and line pressing is adjusted by independent electric motor, and the maximum to minimum size takes only 13 seconds

*Up to 999 sets of dimensions can be entered

*Any group of orders can be output according to the actual demand

*The whole machine can move 50mm left and right, which can effectively adjust the offset of paper web The paper edge suction nozzle adopts electric motor to move left and right

*The crimping device can also be changed to four crimping forms

Copyright:Changzong Precision Machinery Technology Co., Ltd. Phone:13760982599 E-mail:tianzaicheng@163.com

Address:A2, Hesheng Industrial Zone, Sanshan Avenue, Nanhai District, Foshan City ICP:粤ICP备19133286号